Innovation and know-how bring success to our cooperation.

As an subsidiary of Wuchang Group, Zhejiang Lvde Polyurethane Equipment Co.,Ltd is a leading manufacturer of Polyurethane equipment in China . We design and manufacture customized technical solutions to maximizing meet the user's requirements according to different users. Our advanced Polyurethane equipments have led to ever more innovative products and processing solutions, which help to replace conventional materials and manufacturing methods. Our customers directly benefit from our wealth of knowledge and expertise and this strengthens their competitiveness.

Professional research and development and production of high temperature polyurethane elastomeric casting machine, polyurethane soles even help molding machines, high-pressure polyurethane foaming machines, castable polyurethane tires of polyurethane foam and other kinds of equipment.

Discontinuous production

the right solution for special, small or complex applications

The discontinuous production method is mainly used in the manufacture of sandwich elements made of conventional insulating materials. Discontinuous production is also particularly suitable for making elements that have rather difficult shapes at the front or end sides.

Such as Polyurethane-filled panels for structural and insulation applications are produced using discontinuous or continuous foaming systems. Designed to best fit each customer's requirements and budget, LVDE solutions are available in several versions, all characterized by high productivity and optimum foam distribution. achieved with various technical solutions - can be afforded with a lower investment, allows for a more fl exible production mix, permits to customize the panels with inserts and different types of outer faces; all this is obtained with more manpower, lower output and - sometimes - a lower panel's quality depending on the foam-distribution methods employed. exible production mix, permits to customize the panels with inserts and different types of outer faces; all this is obtained with more manpower, lower output and - sometimes - a lower panel's quality depending on the foam-distribution methods employed.

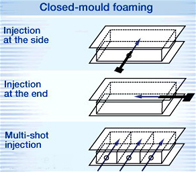

Closed-mould foaming

The way the raw-material is injected into the mould is of great significance in terms of the sandwich elements' quality. The easiest and minimum cost method is spot-shot injection at the side or end of the mould. Multi-shot injection however will increase the foam's quality and the additional use of a drawing technique will also enhance pre-distribution of the reaction mix liquid.

Open-mould foaming

Density distribution will be excellent, if the raw material is dispensed into an open mould. This method usually makes use of a fan-shaped casting rake that will distribute the reaction mixture evenly across the entire element width. Density distribution will be excellent, if the raw material is dispensed into an open mould. This method usually makes use of a fan-shaped casting rake that will distribute the reaction mixture evenly across the entire element width.

Moving or stationary casting rake

Two casting rake arrangements are possible. First, casting rake plus mixhead are moved across the bottom facing material in-side the press. Secondly, the casting rake is fixed at the press' inlet side and the bottom facing will then be drawn underneath the rake as it enters the press. Either one or two mixheads may be used depending on individual output requirements.

LD-602D and LD-602D-Z Large flow of low pressure foaming machine

Maximum mechanization and automation design , Single button operation , automatically tracking , advanced Siemens PLC control system keep the pouring time and pouring is very accurate.

Main application : Oil pipeline , Sandwich panel , large cold store , cold storage etc.

LD-40A series high pressure pouring machine

High pressure design , self-clean L-shaped mixing head , Quality magnetic metering pump . Cooler is options for high temperature seasons

Main application : vehicle (steering wheels , sun visors etc) , furniture (arm rest etc) , Insulation thermal panel , Industrial building, Inner door panel, bear barrel jackets ,toy, Fitness equipment etc.

LD-802G-803G series polyurethane elastomeric pouring machine.

High precise temperature control with hot-oil and hot-wind control unit . Quality metering pump , frequency conversion motor , the precision is 0.5g

Main application : Vehicle wheel , glue roller, filter screens , impeller ,

OA machine, skating roller, buffer Vibration absorption etc.

LD-210-310 series polyurethane molding machine for combined shoes

The mixing head uses Middle –speed mixing mechanism ,The pouring value

with patent never wearing or block, And solve the common problem of time difference in outlet . The mixhead with cooler unit

Main application : shoe soles and upper combined mounding shoes of

bicolor or unicolor polyurethane.

LD602C-603C, series polyurethane elastomeric pouring machine

(three components )

Main application : suitable for hard , high resilient , slow resilient , self-skin formed foaming ,vehicle filter , insulating device , handwheel , vehicle seat cushion , fillings , slab materials , toys , gymequipments etc

LD602B-603B , series polyurethane elastomeric pouring machine

Main application : vehicle (steering wheels , seats ,sun visors etc) , furniture , Insulation thermal panel , filled material ,toy, Fitness equipment etc.

LD-602S low pressure testing machine

Main application: test mould, test sample and production of micro-products. Main application: test mould, test sample and production of micro-products.

Mouldcarrying Systems, Complete Moulding Plants

A very wide range of equipment is available for the moulding process: mouldcarriers, turntables and carousels to hold them, ancillary dosing units for additives, blowing agents, fillers and colors, storage plants, premixing stations, finishing equipment. We provide special project for filling insulation foam in doors and refrigerator cabinets and, for every possible application of Polyurethanes in the automotive field.

Service & Spare Parts

The LVDE provide 360°customer service to our customers before and after the sale of any single product .Years of experience on the field allowed to know and comprehend the specific needs of our customers and to study programs of activities and services to offer to our customer able to satisfy each single request through a fast and easy communication and efficient worldwide services .

Overall before sales technical service

LVDE provide detailed and whole project and solution according to client’s production request including reasonable and optimal technical process and equipments , provide our professional suggestion about A,B material ratio ,technical parameter , assistant unit selection, product quality etc.

Overall technical training service

LVDE organize practical technical training for all customers based on those technicians and machines supervisors who need to be trained on the basic criteria of the use and maintenance ,repair of Polyurethane machines

Professional and practice-oriented trainings for making the best possible use of the performance potential of your LVDE machine and plant technology at competitive terms and conditions.

Significant increase in the quality and productivity of work

Efficient optimization of your production while keeping maintenance costs at a low level

Safety and success of your staff in operating LVDE's machine and plant technology

Targeted and successful elimination of potential failures in the production process

Overall after sales service

LVDE provide overall after sales service in addition to the normal service activities (installation, start-up and testing), including the following :

Technological and technical support

Training of the customers’ personnel for a better use of the equipment related to the production system

Repairs, troubleshooting,

Programmed service maintenances

Control, calibration and certification of the machine critical instruments with relevant certification.

Modification equipment service

Modifications or machine updates to more advanced technologies

Overall after sales global spare parts supply service .

Telephone support to identify the defective part. Reliable availability and fast delivery of original spare parts at favourable prices, original spare parts with manufacturer's guarantee and an attractive price-performance ratio .

Full series spare parts at LVDE stock at any time of the day. Meanwhile ,all LVDE agencies and clients, all over the world, usually manage a consistent spare parts stock for some frequent worn parts.

The majority of our parts is on the way to you within 4-6 days and can be followed up via waybill.

Polyurethane raw material

LVDE does not manufacture or sell polyurethane raw materials, semi-finished or finished products. But We also supply quality raw material according to clients’ products and technical request as an agent.

|